|

| November 24, 2015 | Volume 11 Issue 44 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

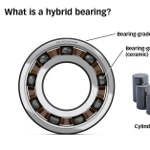

Why hybrid bearings are becoming the new industry standard

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

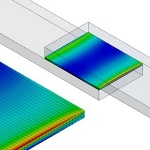

3M and Ansys train engineers on simulating adhesives

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

What can you secure with a retaining ring? 20 examples

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

From the watch dial on your wrist to a wind turbine, no application is too small or too big for a Smalley retaining ring to secure. Light to heavy-duty loads? Carbon steel to exotic materials? No problem. See how retaining rings are used in slip clutches, bike locks, hip replacements, and even the Louvre Pyramid.

See the Smalley design applications.

Load fasteners with integrated RFID

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

A crane, rope, or chain may be required when something needs lifting -- plus anchoring points on the load. JW Winco offers a wide range of solutions to fasten the load securely, including: lifting eye bolts and rings (with or without rotation), eye rings with ball bearings, threaded lifting pins, shackles, lifting points for welding, and more. Some, such as the GN 581 Safety Swivel Lifting Eye Bolts, even have integrated RFID tags to clearly identify specific lifting points during wear and safety inspections and manage them digitally and without system interruption.

Learn more.

Couplings solve misalignments more precisely with targeted center designs

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

ALS Couplings from Miki Pulley feature a simplistic, three-piece construction and are available in three different types for more precisely handling parallel, angular, or axial misalignment applications. The key feature of this coupling design is its center element. Each of the three models has a center member that has a unique and durable material and shape. Also called a "spider," the center is designed to address and resolve the type of misalignment targeted. Ideal for unidirectional continuous movement or rapid bidirectional motion.

Learn more.

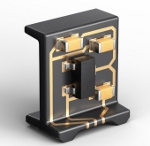

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

U.S. Army engineers use ultrasound to develop safer, better ordnance

By Lauren Poindexter and Ed Lopez, Picatinny Arsenal, NJ

Engineers at Picatinny Arsenal are using ultrasound technology to more easily find defects during the manufacture of ordnance as a way to lower costs, produce more effective ordnance, and provide an added measure of safety for Soldiers in the field.

Engineers at the Armament Research, Development and Engineering Center (ARDEC) want to remove the "black box" that surrounds the production of energetic materials. In the context of defense research, "energetics" is a short-hand term for materials such as explosives, propellants, and pyrotechnics.

"We have this black box, and it's currently hard to see inside with the technology that is available," said chemical engineer Viral Panchal.

"Ultrasound gives us the ability to open up the box, leading to more effective research, development and manufacturing," Panchal added.

Viral Panchal and Rajen Patel, engineers at the Armament Research, Development and Engineering Center, display the pieces that make up the ultrasound technology for propellants. [Photo by Todd Mozes]

ARDEC engineers have been working with Wes Cobb at the University of Denver, who has decades of experience developing ultrasound technology for the food, oil, and medical industries.

The ARDEC engineers provide expertise regarding the energetic material, explaining what properties need to be measured, and Cobb develops tools to do so. The technology developed by Cobb allows for faster research and development that will aid in developing better manufacturing models.

Ultrasound technology for energetics research is used as an in-process research and development tool, which ARDEC engineers and contractors are validating in a manufacturing setting.

Advantages of ultrasound include the ability to capture extensive information in real time, easily pass through metal, and operate at low energies, leading to safe use with energetic materials. Ultrasound technology also provides two useful measurements to include measuring the speed of sound and attenuation vs. frequency during real-time monitoring.

Project Director Joint Services, which is part of the Program Executive Office for Ammunition at Picatinny, is the main sponsor for the use of ultrasound technology in energetic manufacturing. It has made a significant investment in instruments to examine the melt-castable explosive fills for mortar and artillery shells during the casting process.

The Small Business Innovation Research program provided funds to Applied Sonics Inc., which was then able to create key components for the ultrasound equipment. This early investment enabled PM JS to fully support the implementation of the technology to manufacturing lines.

Much of the Army's ordnance items are manufactured as explosive materials cast into shell cases (TNT, Comp B, IMX-101 etc.). The solid explosive materials are first melted in a mixing kettle, stirred, and then poured into an empty shell.

Ideally, the casting hardens from the bottom up and evenly fills the case. However, variations in source materials and process conditions can lead to defects such as piping (vertical holes), porosity, and separation between the explosive and the case.

These defects, if found, lead to increased production costs and, if not, can ultimately affect the safety of Soldiers in the field if a loaded projectile with a cast defect is fired.

Currently, there is no way to monitor the quality of the explosive fill at any time during casting.

Recent work has shown that noninvasive ultrasonic sensors can be used to continuously monitor the solidification process during the casting of munitions and detect the formation of defects.

The monitoring technique can use sensors that are explosion-proof, operator friendly, intrinsically safe, and non-destructive to production rounds.

The sensing technology can measure in real time, at a high rate, providing valuable information that will eventually be incorporated into a control system.

"Energetic material manufacturing equipment is out of date, and the origin of flaws is difficult to understand as most available sensors cannot withstand the harsh manufacturing environments," said ARDEC engineer Rajen Patel.

"We had a program started several years ago that examined explosives for internal cracks, density, and viscosity in melt pour formulations. We were able to show that using ultrasound we can collect this information in real time."

Ultrasound with propellants

ARDEC engineers are also currently working with University of Denver to apply ultrasound technology to propellant manufacturing. Propellants are chemical substances that burn rapidly and generate gases, which push bullets or rockets downrange.

Previously, there were a number of methods in place to examine propellants, including X-ray imaging to check for the presence cracks and defects, buoyancy measurements for density, and viscometers to measure viscosity.

These properties are important for the quality of the materials and repeatability of propellant performance.

"Propellants are typically fabricated by mixing both solid and liquid ingredients with a suitable solvent system in batch mixers," said Panchal. After mixing, the product has a tough, dough-like consistency, which is then placed in an extrusion press and squeezed through a die of desired geometry to form strands.

"The strands are then cut into specific lengths to meet ballistic burning rate requirements," Panchal added.

"These cut grains are then blended together to make up the final propellant lot."

The propellants are then thoroughly analyzed afterwards.

"Moving forward, the goals for the project are to reduce the scrap rate and the number of voids in the propellants, while eliminating the blending cycle to reduce lot-to-lot variation.

"This will result in a more consistent product the first time rather than remaking substandard propellant lots at increased time and costs," added Panchal.

"Propellants often have a range of solvent content as they are extruded, and this solvent needs to be removed from the final grains through subsequent drying steps," he continued.

"Knowing the solvent level at the extrusion press allows the propellant manufacturer to tailor the diffusion rates of the solvents, controlling how they exit the propellant so that the formation of potential voids and cracks in the grains can be reduced.

"If you can detect the solvent levels at the time of extrusion, you can correct manufacturing defects in real time."

Real-time monitoring

An operator sitting in the control room can monitor the process and the solvent level in real time so that potential problems can be identified early, reducing production time, saving money, and boosting product quality.

"Nothing before could tell you in real time about the product quality," said Panchal.

Ultrasound technology allows the operators to stop at any point during production to address potential problems early on, instead of having to scrap an entire batch.

"We can eventually transfer this technology to our manufacturers to get a higher quality, more consistent product at a lower price," said Patel.

"It will reduce scrap rates and lower production times," he added.

Published November 2015

Rate this article

View our terms of use and privacy policy